MUDANJIANG NORTH ALLOY TOOL CO., LTD. FOUNDED 2006,IS THE EARLIEST MANUFACTURER OF CEMENTED CARBIDE AND TUNGSTEN ALLOY PRODUCTS IN CHINA. SPECIALIZING IN THE RESEARCH AND DEVELOPMENT OF NEW MATERIALS, NEW PROCESSES AND NEW TECHNOLOGIES OF TUNGSTEN ALLOY POWDER METALLURGY. THE COMPANY'S PRODUCTION CAPACITY AND RESEARCH AND DEVELOPMENT LEVEL OF HIGH-PERFORMANCE FORGED TUNGSTEN ALLOYRODS, TUNGSTEN ALLOY FRAGILE MATERIALS AND ENERGY RELEASING MATERIALS ARE LEADING THE TUNGSTEN MATERIAL INDUSTRY.

Material: W content 80~97% W-NI-FE, W-NI-CU Diameter: 2.5~260mm Tolerance: Usually ±0.02mm Density: 15.5~18.65g/cc Surface: sinter state or grind state UTS: 600~1000MPa Hardness: 22~35HRC Elongation: 1~25% Applications: Used as fishing weight, ballast, decorative balls, automatic oil seal valves and shotgun shells. It can also be applied to the military field as prefabricated fragments and other purposes. We can offer tungsten alloy balls of various grades and sizes. Each process is strictly required to ensure that the products produced strictly comply with your requirements.

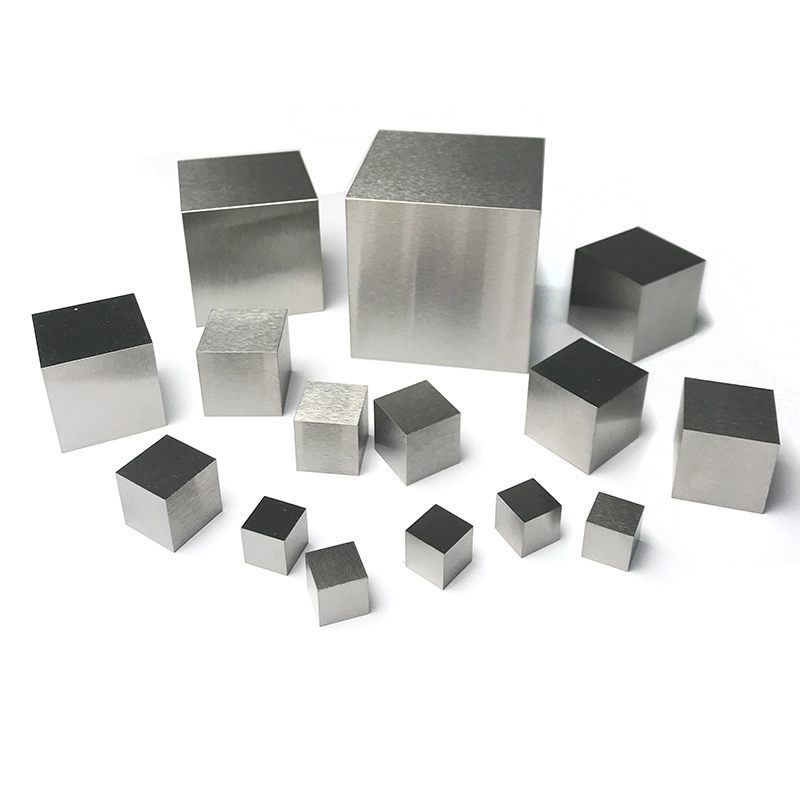

Material: W content 90~97% W-NI-FE, W-NI-CU Size: 2.5~180mm Tolerance: Usually ±0.02mm Density: 15.5~18.65g/cc Surface: sinter state or machined state UTS: 600~1000MPa Hardness: 22~35HRC Elongation: 1~25% Applications: It can be used in the military to preform fragments and make parts. It also can be used as counterweight parts such as speedboat counterweight parts, vehicle configuration parts, aircraft counterweight parts, helicopter counterweight parts, ship counterweight parts and tank counterweight parts. Especially due to the radiation absorption capacity, tungsten alloy blocks are now widely made into components used in the medical field, such as radiation shielding walls, CT etc.

Material: W content 90~97% W-NI-FE, W-NI-CU Diameter: 3~260mm Length:3-900mm Tolerance: Usually ±0.02mm Density: 15.5~18.65g/cc Surface: sinter state or machined state UTS: 600~1450MPa Hardness: 22~35HRC Elongation: 1~25% Applications: Can be used for dart billets, oil detector weight rod, applications on aircraft, ships, nuclear submarine in the gyro rotor, counterweight parts; and the balance weight in the engine. Tungsten alloy rods can also be used for radiation shielding devices in radio logical medicine, and for gamma source protection devices in geological exploration.

Material: W content 90~97% W-NI-FE, W-NI-CU Diameter: 2.5~15mm Length:2.5~50mm Tolerance: Usually ±0.02mm Density: 15.5~18.65g/cc Surface: sinter state ormachined state UTS: 600~1450MPa Hardness: 22~35HRC Elongation: 1~25% Applications: It could be used for golf club weight, car weight, bicycle weight, clock weight, mobile phone vibrator weight and so on. In the military field used as kinetic energy armor piercing material, prefabricated fragment material, etc.

Material: W content 90~97% W-NI-FE, W-NI-CU Max Size: OD200*ID1808H10 Density: 17.0~18.65g/cc Surface: sinter state or machined state UTS: 600~1450MPa Hardness: 22~35HRC Elongation: 1~25% Applications: It could be used for aircraft weight, automobile weight, clock weight, mobile phone vibrator weight and so on. In the military field used as kinetic energy armor piercing material, prefabricated fragment material, etc.

Material: W content 90~97% W-NI-FE, W-NI-CU Sizes: according to the drawing Density: 17.0~18.65g/cc Surface: sinter state or machined state UTS: 600~1450MPa Hardness: 22~35HRC Elongation: 1~25% Applications: It could be used In the military field as kinetic energy armor piercing material, prefabricated fragment material, etc.

Material: WC content 90~97% WC-Co Sizes: according to the drawing Density: 13.5~15.0g/cc Surface: sinter state or machined state TRS: 1700~3000MPa Hardness:85~92HRA Applications: It could be used In the military field as kinetic energy armor piercing material, prefabricated fragment material, etc.

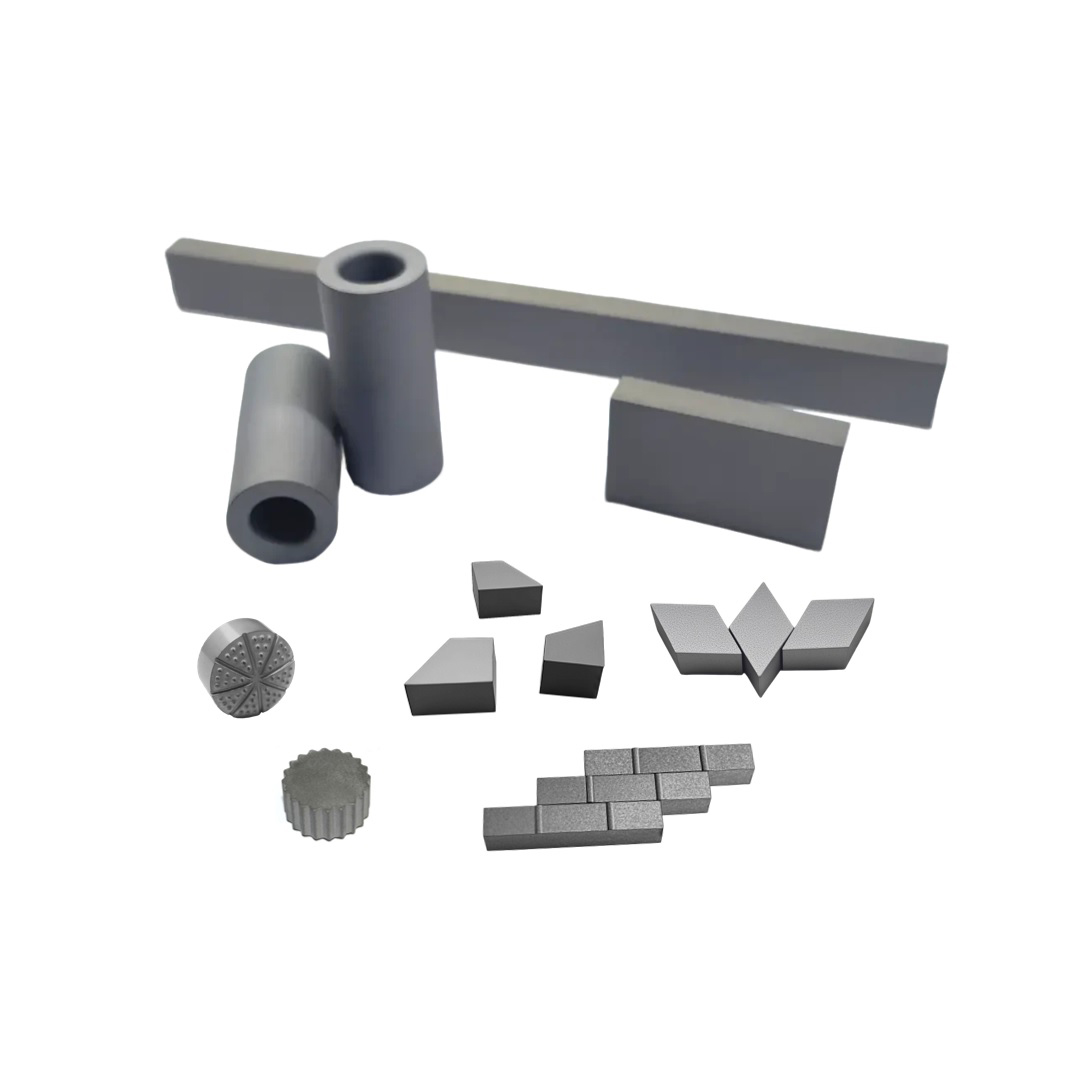

Material: WC content 88~94% WC-Co Sizes: according to the drawing Density: ≥13.9g/cc Surface: sinter state or machined state TRS: ≥2200N/mm2 Hardness: ≥86 HRA Applications: High wear resistance and impact toughness, used in the production of various metal stamping mould, precision mould, drawing mould and powder metallurgy mould. Including a variety of carbide precision parts, wear-resistant parts. used in many mechanical products of wear-resistant fields. The cutting blade is used to cut and wash the work piece in machining.

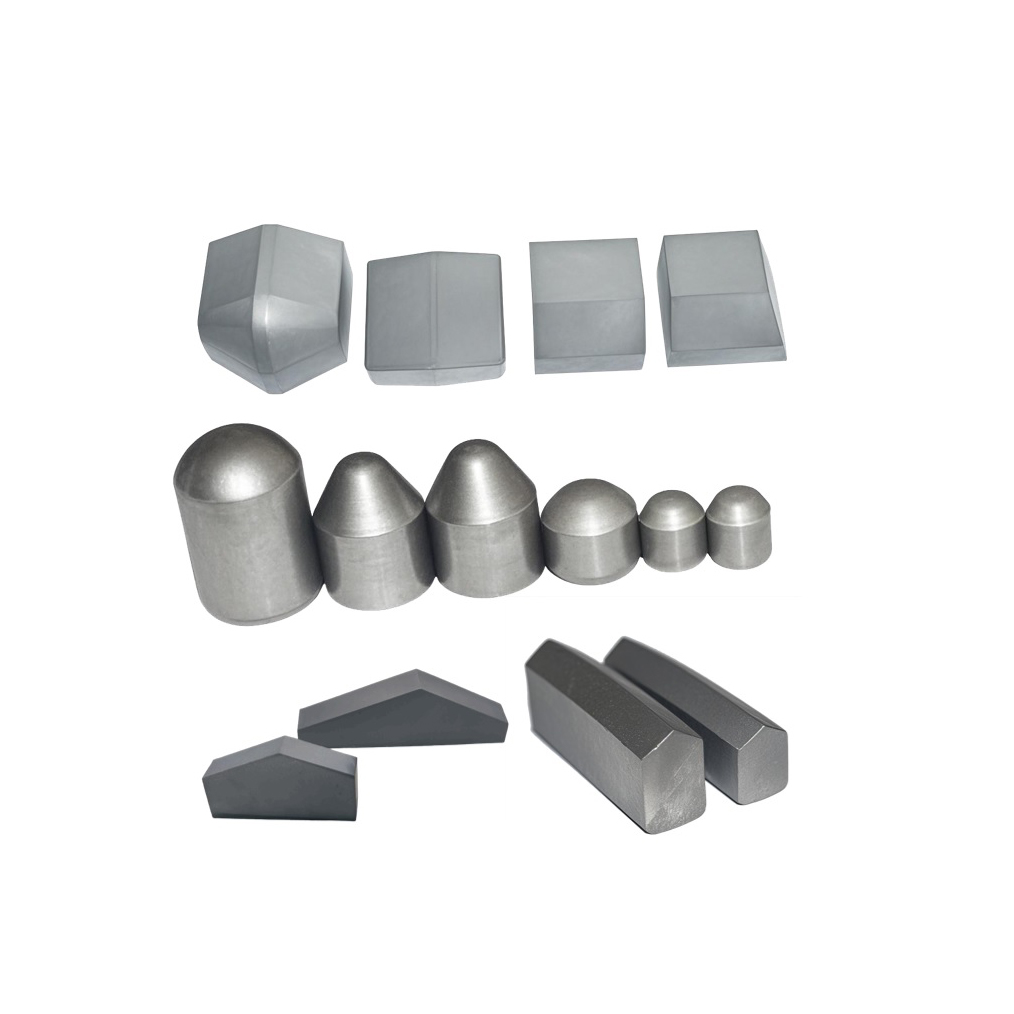

Material: WC content 88~94% WC-Co Sizes: according to the drawing Density: ≥13.9g/cc Surface: sinter state or machined state TRS: ≥2200N/mm2 Hardness: ≥86 HRA Applications: Cemented carbide teeth with high wear resistance and impact toughness are used for the production of various down-hole drill, roller drill, shield cutter, coal mining tools etc.they are widely used in mining and oil exploitation, tunneling and other industries. We can provide all kinds of button tips according to the drawings and samples including non-standard styles